wjrii

- 9 Posts

- 74 Comments

5·1 year ago

5·1 year agoNo need to go crazy with the first one. That first step from laptop keyboard or membrane pack-in is the biggest jump you’ll ever make in typing experience. a brown-switch gamer board with the RBG turned off and some cheap Amazon “CSA” style keycaps might be all you’d ever need. Of course, even that type of thinking can lead to certain… rabbit holes.

6·1 year ago

6·1 year agoI never truly learned to type, though I had a few weeks instruction in school, and did a few levels of Mario Teaches Typing when I was a kid. None of it really stuck, and typing remains an exercise in hand-eye coordination for me. I topped out at around 70-80 WPM if I’m composing rather than copying, but that’s been good enough for a lifetime of office jobs, and certainly for writing school essays. There is definitely a lower ceiling if you don’t get proper instruction, but simple practice is still helpful.

26·1 year ago

26·1 year agoDrawing an imaginary factory- and they wanted kids to do this before teaching them the parts of the cell- isn’t going to help you learn what mitochondria are.

That sounds like it’s an exercise meant to get the kids thinking about a multi-faceted system existing inside a single structure, with parts that are interconnected but distinct, and will lead into a common metaphor teachers use to teach about biological cells. Not being graded means they’re not judging the kids on what they know or don’t, but want to evaluate where they are with this sort of thinking and figure out what they will focus on. Also, your kid may be smart and already know where they’re going with this, but others in the class may not. If she does, she could probably knock that out in fifteen minutes. Even if you decide that she doesn’t need to do it, I don’t think it’s stupid busy work, at least not necessarily.

Some teachers are dumb; we need too many of them and pay them too little for each and every one to be a superstar. The ones coming up with curricula and lesson plans usually aren’t, though.

2·1 year ago

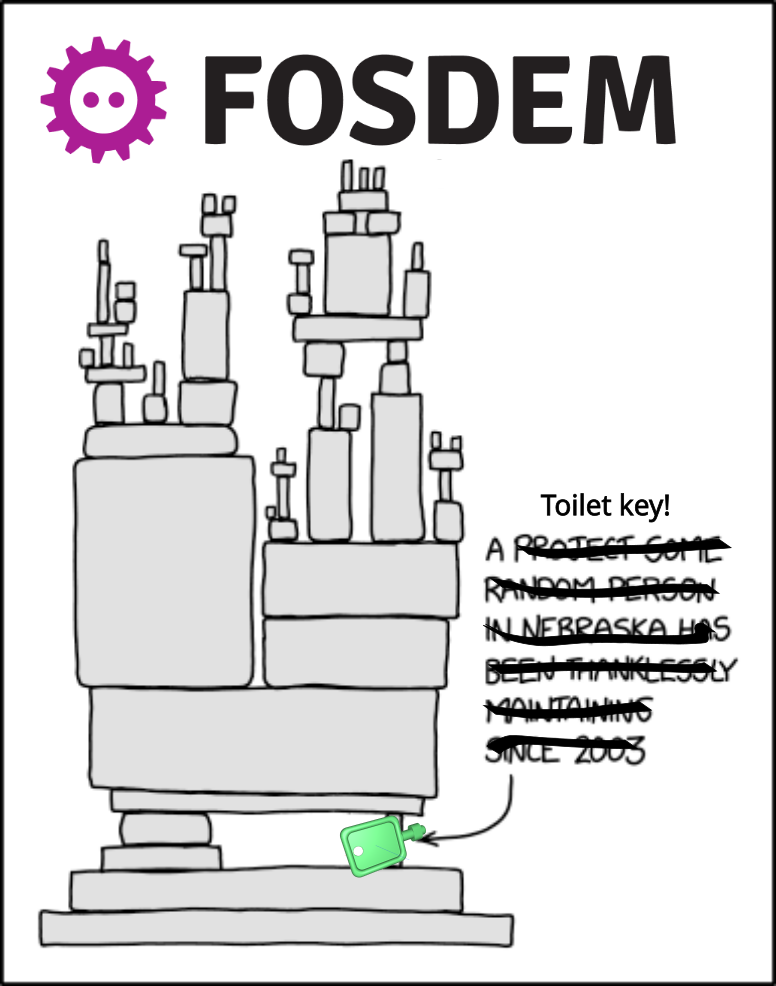

2·1 year agoAbiword is okay for now, I guess, but it’s basically a zombie, waiting for dependencies to break:

https://forums.linuxmint.com/viewtopic.php?t=412196

4·1 year ago

4·1 year agoAll those firmwares work fine, or even better, over USB. Of course, there’s also the option to simply buy a kit. No idea if these people are legit, but the tech itself looks simple enough, a circuit board with contacts that let the linkage make a connection.

7·1 year ago

7·1 year agoI am not quite sure I’d be ready to recommend it, but your more adventurous patrons may want to experiment. These keycaps are PBT, a cousin of polyester. They are not particularly pleasant smelling when heated or especially when burned, but they’re not as unhealthy as ABS (the other common plastic for keycaps) and certainly not as bad as the straight up poison gas that comes from PVC. I use a basic 5W blue diode laser, coat the keycap with an “infusible ink” pen from Cricut (most of their infusible products are polyester-based), put it in an alignment jig, then laser a raster image “low and slow.” My particular laser seems to do best when I do two or three passes at 2% power and 45mm/minute. The idea is to heat it roughly in line with the crafting heat presses without letting the heat spread and color in areas beyond the beam. I experimented with actually burning or engraving, and that sort of works, but (1) it’s stinky, and (2) the ash wipes away and you’re left with a mostly colorless letter-shaped indentation. The “dye sub” technique produces barely any fumes at all. There are a few people on youtube who’ve tried similar techniques, and quite a few who have used different heat or dye sources.

Aesthetically, the process was only marginally successful, though I’m optimistic about the longevity, at least compared to other low-end manufacturing techniques. I’ve been using a similar set of home-lasered keycaps for about a month with little to no wear. My jig was not as good on that set, AND I tried to center the keycap legends, meaning every fraction of a millimeter was painfully obvious. These legends didn’t end up exactly where I might have liked either, but they’re all off by the exact amount (about 1mm), so being consistent, the alignment isn’t too bad.

6·1 year ago

6·1 year agoIt should be doable. The way these things are wired, you wouldn’t use a common. You’d instead wire a matrix with diodes to avoid ghost presses. The firmware on the arduino or RPi microcontrollers will constantly scan for keypresses. So much would depend on the exact mechanism of your typewriter, but you could find a place where a keycap moves parts in close enough proximity to make your own switches, or if some part of the mechanism presses straight down, you could just have that actuate mechanical keyboard switches.

For wireless, you’d probably want ZMK. QMK is the most famous, but ZMK supports more wireless MCUs. I use KMK, a firmware where everything is human-readable python. I understand it has some wireless support, but I’ve never looked into it.

7·1 year ago

7·1 year agoDoing it on the keyboard could very easily work, but I have a laser-cut jig that holds twenty-six 1u keycaps, and has one open-ended spot for anything up to maybe 3u. I considered 3D-printing the jig, but 30 minutes on the laser made more sense than 5 hours on the printer.

This plastic didn’t love my “Infusible ink” pens, so the legends are duller than the last time I did this, but the jig helped a lot with alignment, as did adjusting my ambitions and expectations. Much less disappointing to land 1mm off when you can pretend you wanted it there all along, and that is much easier to do with corner legends versus centered. :-)

7·1 year ago

7·1 year agoThanks. Kind of a 2004 Apple and Logitech thing going. Probably need another couple of years before it’s in vogue. white filament on the printer though, so white keyboard it is.

putting another tab button on the numpad

Horizontal spreadsheet data entry, my friend. it’s probably one of the less crazy parts of this layout! Of course, ten minutes on the laser and/or 5 in the software, and I can make it any key you need. Programmable keyboards are a godsend when you’re winging it on the layout.

Would it be better or worse if the most popular large breed in the world were not erroneously referred to as a “Labrador” retriever?

Also, hello cousin. I’ve never been within a thousand kilometers of Newfoundland – Boston or Montreal is as close as I got – but I found out as as a grown-ass, gator-swimmin’, boild-pnut-eatin’ Florida-man that my biological grandmother was born and raised in Clarenville. Apparently, I have relatives from Moncton to St. John’s to Toronto to Fort McMurry to Vancouver, and damn near every single one of them is mortified that that Granny’s boy had a one night stand in the '70s. 🤣

At my rather beginner level, designing single parts for a 3D printer or laser engraver, it behaves almost exactly like most other parametric-history CAD apps in the broad concepts. The devil is just in the details, really. Shortcuts are different, terminology is different, Certain QoL and UI elements are either missing or somewhere else. The workbench model is not unique, but some of the kruft that has built up around FreeCAD’s benches and the defaults (better in recent versions if you look at the start screen) can make a new user “nope out” if they have other options. I guess assemblies in particular remain a fragmented area and lag behind the commercial packages, and I can say for certain that it still requires “good design practices” in a way that some of the commercial apps manage around, toponaming the biggest among them.

If all the negatives kill your workflow to the point that you want to pay for commercial software or live with the limitations (current and potential) of their free tiers, then that’s absolutely understandable. Commercially, it’s doubly so, and with addition of the “business reality” that there’s also no one to blame or sue if FreeCAD is not working for you. Hell, I don’t use it for all my stuff either, as I find no-history modeling still mostly works for what I’m doing and I have some free or cheap options in that space that are decent, but I can see the appeal as I’m starting to make things that could benefit from tweaks after the fact. What I get frustrated by is claims that FreeCAD “is no good” or “will never be useful”. I call BS. It’s already good and useful for many use cases, and anyway the number of free parametric CAD suites that do not restrict your use of your designs is exactly ONE. Otherwise, you’re looking at an absolute minimum of $300 a year to subscribe and hope that Shapr3D’s new history functionality doesn’t break, and that neither they nor Alibre gets gobbled up.

It’s getting better, and it’s critical that it do so, if for no other reason than to raise the floor that commercial offerings have to surpass to retain small-to-medium customers. I haven’t committed to it, but I’m rooting for it and following it closely.

1·1 year ago

1·1 year agoWhite filament and a sharp pocket knife hide many sins, but thanks. It came out quite okay, and the cheap hardboard from Home Depot cuts very nicely with even a cheap laser.

1·1 year ago

1·1 year agoIt’s actually not secured yet. I included a couple of hexagonal openings in the long legs of the print that should accommodate a heated brass standoff just about right; it’ll be very similar to your alignment pins. I used the idea on my last keyboard and it worked well. The gap will be closed a bit more after securing the screws from the bottom plate. It will be nowhere near “perfect,” and but the end result should be a bit cleaner than this in-progress state. I am fairly pleased how decorative grooves draw the eye away from the seam a bit, but I’m not really trying to hide that it is 3D printed, and that in two pieces.

2·1 year ago

2·1 year agoTree supports and careful use of an exacto knife could also make it work. Post processing can be a bit much sometimes, but it doesn’t have to be the enemy either.

2·1 year ago

2·1 year agoBLENDER’S NOT CAD! ;-)

I mean, depending on one’s definition, either it is or it isn’t, and with CAD extensions I imagine it’s perfectly fine for 3D printing where everything ends up a mesh anyway, but pretty much everything I’ve ever made was better suited to a solid modeler. I downloaded it once, but there was a lot going on there, and since it wasn’t my priority to learn to sculpt, I set it aside.

1·1 year ago

1·1 year agoWhen is the last time you tried? 0.21 is better, and the new Ondsel build based on 0.22 is even a little bit better still. The skills (and mine are, frankly, below average) from Fusion360 should translate; under the shiny pull arrows, they’re obviously very similar. It’s all the same concepts, and constraints are less critical than they first appear for making one-off parts.

Then, if you don’t share my concerns with OnShape, it should work very well in Linux and after hitting F11 you might just forget it’s browser-based.

1·1 year ago

1·1 year agoI understand the 3D experience includes some sort of browser-based riff on SW; maybe that would be a halfway useful tool for Linux. I dunno. :-)

My very first “design” was cord wrangler that fit the exact number of things I needed to charge and was the exact thickness for my no-name pressboard nightstand with a gap that matched an opening in the back. It was exactly what I needed.